In recent times when urbanization is at its peak, people are turning more towards budget-friendly options about various aspects of their lifestyle to save on some unnecessary expenses. The recent rise in the startups that provide rental services, has made people’s lives very easy.

Right from renting the house to

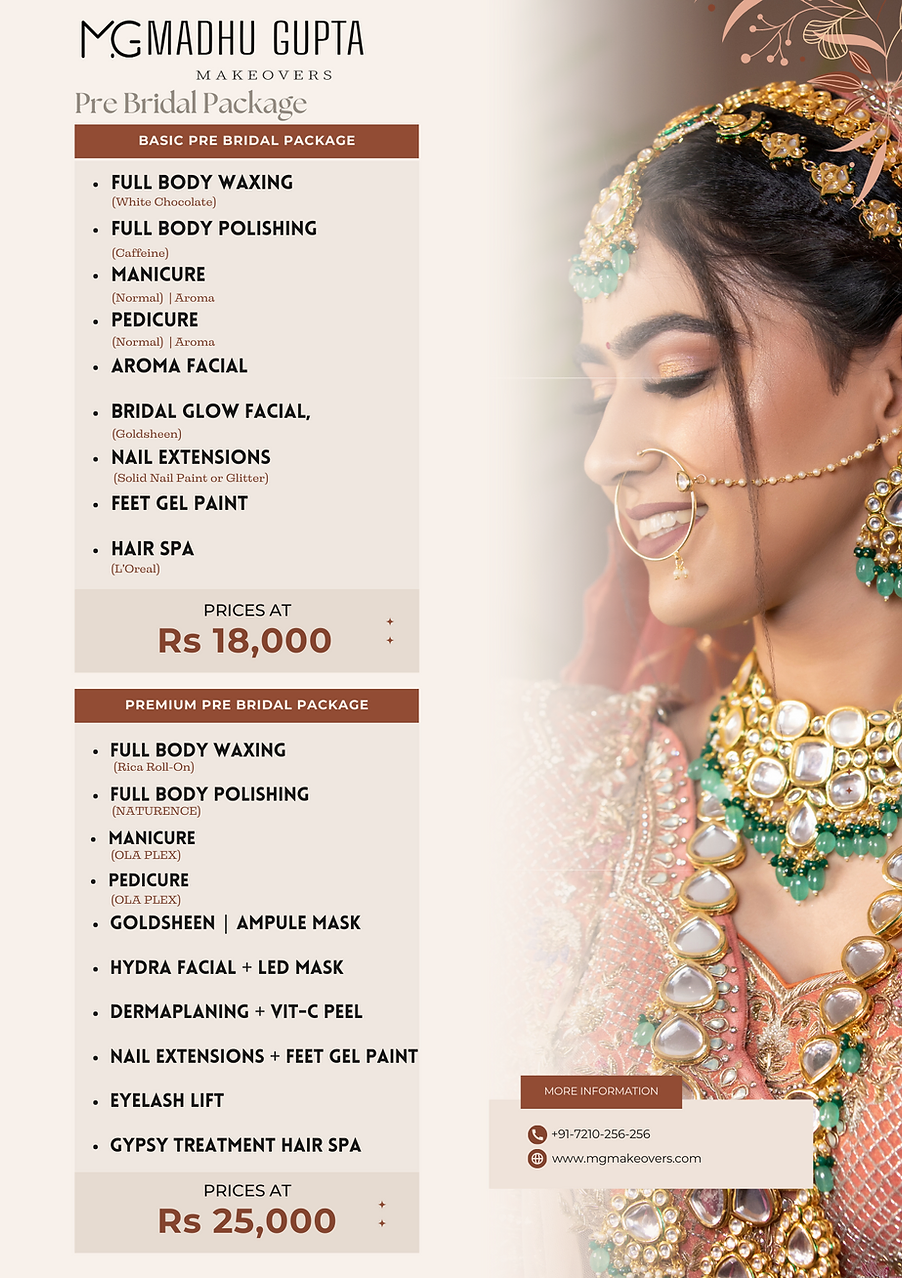

As the big day approaches, every bride dreams of looking her absolute best as she walks down the aisle. While the dress, shoes, and accessories all play a significant role in achieving that picture-perfect look, it's the pre-bridal makeup services that truly elevate a bride's beauty to ethereal heights.

Imagine stepping barefoot onto your perfectly manicured lawn without any fear of encountering an unwelcome surprise – a prickly thistle or a stubborn patch of crabgrass lurking beneath the surface. Sounds like a dream come true? Well, with our comprehensive guide on weed control in Minneapolis, that dream can

Buckle up and fasten your seatbelts because we're about to take you on a thrilling journey through the world of ultimate luxury car services. Imagine sipping on champagne while cruising down the streets in a sleek, powerful sports car. Picture yourself being whisked away to exclusive events and parties,

In today's digital age, gaming has evolved from a solitary pastime into an immersive social experience where players from across the globe connect, compete, and collaborate in virtual worlds. What makes this shift even more fascinating is the rise of user-generated content - where gamers themselves become creators and